Nickel-Diamond Coating technology by Pulsed Electrolysis

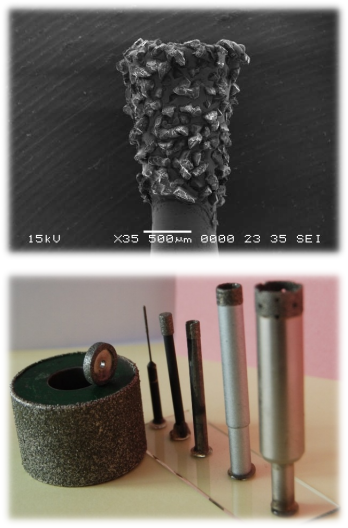

The production of diamond tools for industry and dentistry; the application of thick electroplated coatings.

Brief description: current density upon receipt of composite coatings 5-30A/dm2; cathode pulse duration 5-50 ms, coating thickness up to 400 microns; The size of diamond grains in the coating reaches up to 400 microns.

Advantages: the use of non-stationary electrolysis in the production of composite diamond-containing galvanic nickel coatings allows you to:

deposit coatings 5-10 times faster than conventional electrolysis;

receive various types of coatings, changing only the electrical parameters of electrolysis;

receive coatings without brightening additives in the electrolyte.