The new 3D printing method allows efficient electronic circuits to be produced at high speed

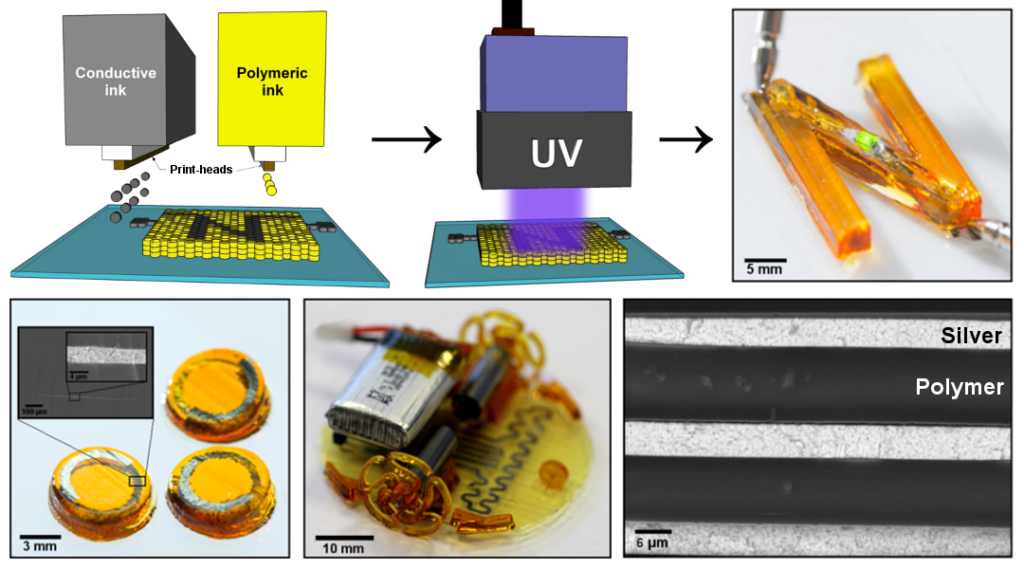

Researchers from the University of Nottingham have developed a new 3D printing technology that can produce workable electronic circuits and additional components such as antennas, sensors and photovoltaic cells at a fairly high speed. The new 3D printer is capable of working with two types of “ink,” a silver-based metal ink, and an insulating polymer material. A regular ultraviolet lamp is used to quickly polymerize and give strength to the printed product.

The multifunctional additive manufacturing (MFAM) is a combination of 3D printing and the printing method of two-dimensional electronic devices. The MFAM printer is able to print both electric conductors and insulation, which is the basis of the design of the future product, during a single passage. The only thing that a 3D printer can’t do is the manufacture of electronic components themselves, both simplest, such as resistors and capacitors, and highly integrated, such as chips. All these elements are installed and soldered later by a human or specialized robot.

During the work, the researchers found that the silver nanoparticles, which are part of the current-conducting ink, quite effectively absorb ultraviolet light. The energy of this light causes the nanoparticles to heat up to a temperature at which solvents evaporate and at which the nanoparticles are qualitatively fused with each other. And this process affects only the conductive parts, without affecting the parts of the polymer-insulator.

The new method overcomes some of the problems of single-stage production of fully functional electronic devices, which usually contain polymer and metal components, combined into one complex structure. Thanks to the new approach of using ultraviolet light, the process of hardening the conductive parts is done in less than a minute. In other similar methods, the caking of silver nanoparticles was produced much longer with external heaters, which is highly impractical when it is necessary to process hundreds of layers to form the final produc

t.Source www.dailytechinfo.org