3D printing with laser holograms will ensure the creation of complex shapes in seconds

Additive manufacturing, better known as 3D printing, today allows scientists and engineers to effortlessly create designs and configurations that were previously extremely difficult to do. But even now, the alternate overlay of layers during the construction of a three-dimensional object takes hours, and sometimes the whole day.

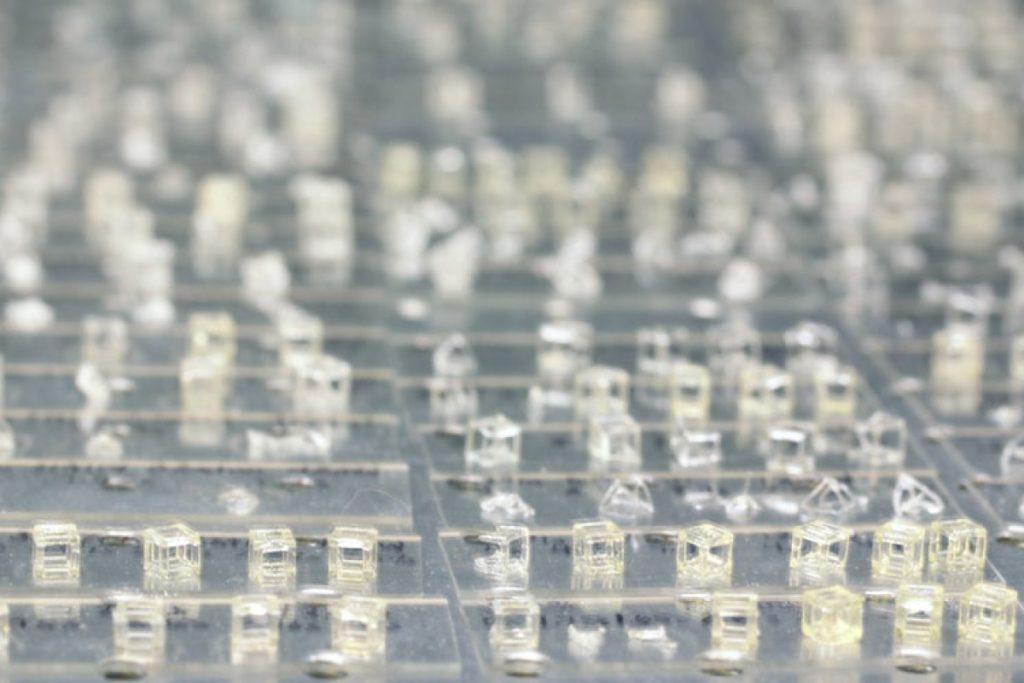

Researchers from the Livermore National Laboratory (LLNL) and their colleagues at the University of Rochester were able to invent a much faster way to create complex 3D models. The traditional printing of products will be replaced by a different process. Lasers will create three-dimensional images like holograms displayed in a light-sensitive solution based on rubber compounds. As a result, grates, connections, fasteners and their faces at different angles can be quickly sealed. It was possible to create complex, originally curved parts within a few seconds. The new method was called “volummetric” (volume) 3D printing and was described in the December issue of Science Advances.

“The fact that we can do full three-dimensional details in one step today shows serious progress in additive technologies,” said LLNL researcher Maxim Shustev, author of the publication.

Speaking about the mechanism of the new device, Shustev drew attention to three overlapping laser beams, which in different directions determine the geometry of the future product. At the intersection of rays, the intensity of laser light is so high that 10 seconds is enough for the volcanization, hardening of the material. The remnants of the solution are pumped out and as if by magic we are left with a fully finished three-dimensional object.

This way of printing products is many times faster than using any other existing methods. Due to the low cost, flexibility of settings, speed and versatility of geometry of the new equipment, according to the researchers, a new direction in the high-speed 3D printing industry can be considered open.

While traditional 3D printing carries some difficulties associated with the sagging of suspended elements of finished products, according to Maxim Shustev, no supporting devices are needed in bulk printing. Sticking to the old printing technology means to abandon the qualitative construction of cross-section and guides. “I hope our work will inspire other researchers to find more ways to make such items using other materials. This could mean a shift in the whole paradigm in production,” Shustev added.

With more powerful light sources, 3D printing can be done even faster. Also, according to scientists, in such a process it is possible to use ultra-soften materials such as hydrogels.

However, there are still limits. Creating extremely complex structures requires many intersecting laser beams. It’s hard to do so far, but researchers hope to solve this problem as we

ll.Source:ecotechnica.com.ua