Fujitsu has developed a material with a record performance of thermal conductivity

Almost at the end of last year, Representatives of Fujitsu announced the development of a process for the production of sheets of material consisting of multi-wall carbon nanotubes. These nanotubes are located perpendicular to the plane of the material and it is in this direction that this material has the highest thermal conductivity to date. Products made from this nanotube material, formed in a certain way, can act as an effective heat drain for electronic devices, including silicon carbide power devices used in modern electric cars.

According to the results of the tests, sheets of nano-cutting material are able to conduct and dissipate heat from an efficiency of 80 watts per meter per degree kelvin. This is about three times more thermal conductivity than the thermal conductivity of sheet indium, a material used in some areas to provide high-efficienc

y cooling.The biggest problem that Fujitsu has successfully solved is the problem of growing homogeneous carbon nanotubes through the chemical deposition process from the steam phase. After all, at the slightest deviation from the norm of any of the parameters of this process on the surface of the metal substrate begin to "grow" nanotubes of different sizes and specific density. It is this problem that has prevented the emergence of large-scale production technologies for large-scale nanotubes for a long time.

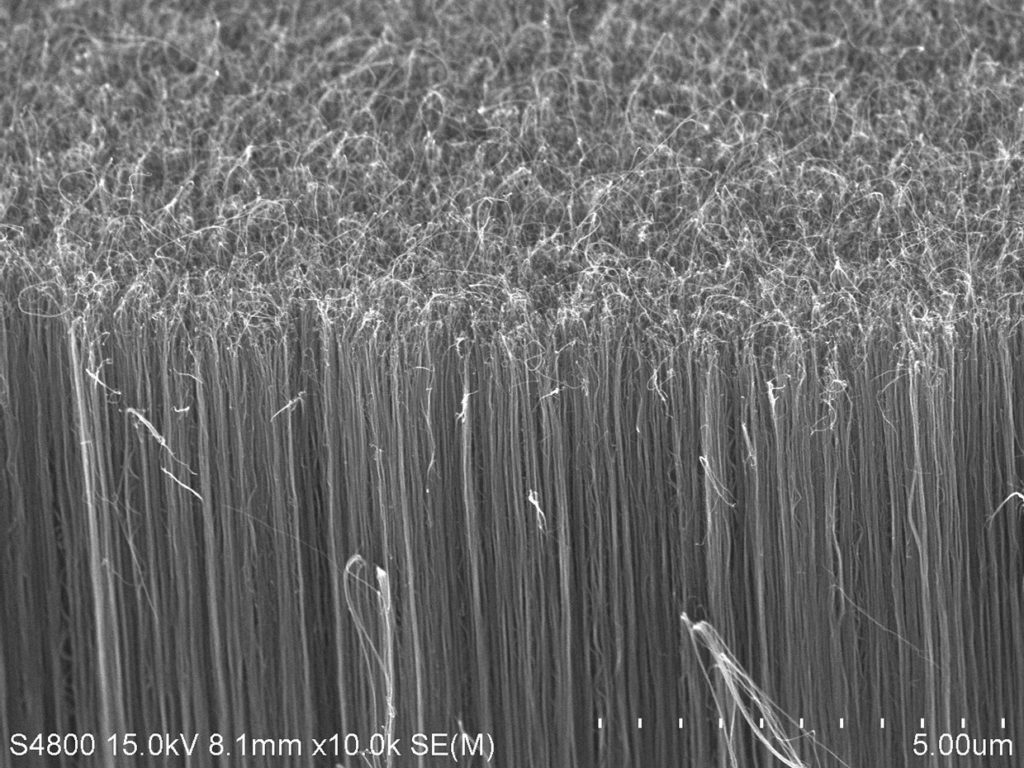

Specialists of the Fujitsu Devices and Materials Laboratory have developed a new process that allows to control the temperature and pressure of gas in the chamber with high accuracy, where the process of depositing nanotubes on the surface, which is applied to the particles of the metal catalyst. All this leads to the growth of the "forest" of homogeneous nanotubes, located strictly perpendicular to the base. The size of the sheets of material that can be produced in this way is limited by the size of the base blanks and equal to 200 millimeters.

The material, consisting of multi-wall nanotubes, which after cultivation undergo a special chemical treatment, can withstand heating to a temperature of 700 degrees Celsius. This is much more than the possibility of leaf india, the melting point of which is about 160 degrees.

Fujitsu intends to commercialize this technology by 2020. But until then, they will have to solve the problem of the high cost of new material, which far exceeds the cost of traditional materials used as a heat drain. This, first of all, can be achieved by improving the process of production of such material. But even without drastic cost reduction, such material can already be used in space technology, high-voltage power electronics and other areas where costs do not play a major role and where effective cooling of devices operating at temperatures of 200 degrees Celsius and above are require

d.Source:www.dailytechinfo.org