Composites for next-generation nuclear reactors created

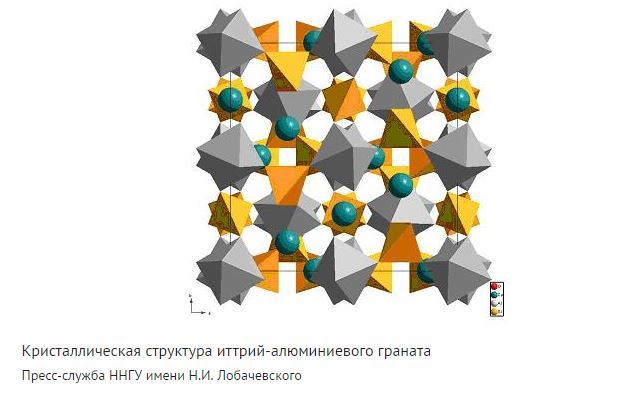

Researchers used a way to obtain composite materials ceramic ceramics and ceramic metal based on mineral-like compounds (in particular, pomegranate). Such compounds will be useful for solving problems with the reserves of plutonium and other transuranic elements (MA, minor actinides) accumulated over the years. The best way out of this situation, according to the researchers, will be the creation of high-density ceramic composite composite fuel matrix (IMF) for the burning of plutonium and transmutation MA. As a result, the authors published two articles: materials Research Bulletin and Materials Chemistry and Physics.

The main drawbacks of mineral-like ceramic materials based on pomegranate, for all their advantages in terms of use in nuclear power, include their low thermal conductivity and low crack resistance. The first factor can lead to additional heating due to radiogenic heat and, as a result, to a decrease in chemical stability. Low crack resistance of ceramics contributes to the appearance of microfractures, which also reduce the chemical resistance of materials.

“In this regard, the idea of creating composites “ceramics – ceramics” and “ceramics – metal” is very promising,” says co-author Lyudmila Golovkin from Nizhny Novgorod State University named N.I. Lobachevsky. “In such a material, with the right choice of component, the second phase (ceramic or metal) could provide both increased thermal conductivity and increased crack resistance.”

“In this regard, the idea of creating composites “ceramics – ceramics” and “ceramics – metal” is very promising,” says co-author Lyudmila Golovkin from Nizhny Novgorod State University named N.I. Lobachevsky. “In such a material, with the right choice of component, the second phase (ceramic or metal) could provide both increased thermal conductivity and increased crack resistance.”

Under the direction of Dr. Albina Orlova of NSU, fine-grain composites based on Y2 grenade were developed and researched.5Nd0.5Al5O12 with additives of high-thuting metals (nickel, molybdenum, tungsten) and silicon carbide, which have a small cross-section of neutron capture. Neodim in the ittria-aluminium pomegranate modeled the presence of ceramics americium and kyuria.

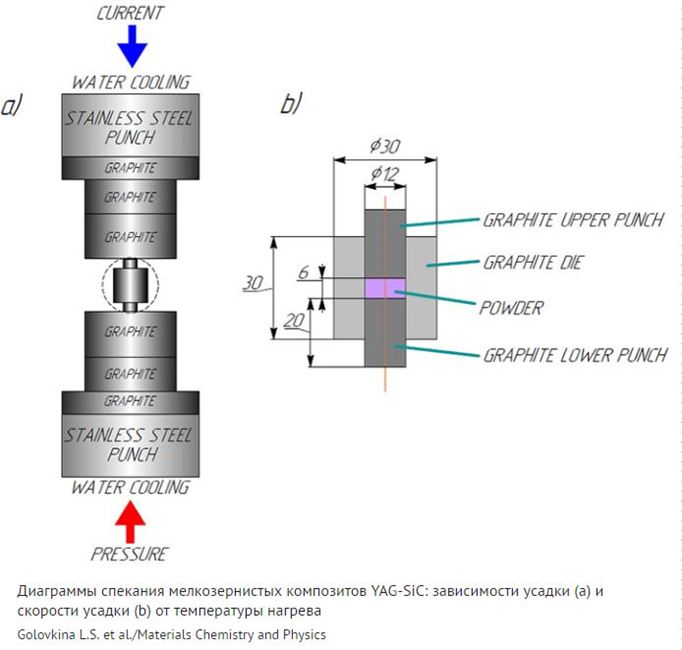

In order to obtain “granat-metal” powder compositions, scientists developed and applied a new way of applying thin layers of metals to the surface of synthesized submicron pomegranate particles. High-speed electropulse plasma baking was used to bake powders and produce ceramics, one of the promising ways to produce ceramics and composites. In the course of this method, the powders are baked at high speed due to the fact that powerful millisecond pulses of the DC (up to 5000 amps) pass through them, while attaching high pressure to them.

As a result, the scientists obtained ceramic composites “granat-metal” and “granat – carbide of silicon” with a high relative density, amounting to 92-99% of the theoretical value for the composites “granat-metal” and 98-99% for the composites “granat- SiC”. “This allowed to ensure high hardness and crack resistance of composites, as well as their high thermal and physical properties (thermal conductivity in the interval of temperatures close to the temperature of use of these materials in new promising reactors on fast neutrons), which, all other things being equal, will reduce the probability and intensity of destruction of ceramics during the reactor operation,” Orlova sums up.

The next step in the development of this work will be to study the radiation stability and resistance to the thermo-impacts of new composites, which will allow us to come close to the task of developing a fundamentally new way to obtain fuel for reactors on fast neutrons, as well as to solve the problem of immobilization of high-active components of radioactive waste by their reliable isolation from the biosph

ere.Source:indicator.ru