Russian scientists have developed a superhydrophobic coating

Russian scientists have developed a superhydrophobic coating for silicone rubber, which is used as insulators for power lines. Coverage was successfully tested in the conditions of the Moscow winter. Research by a scientific team from the Institute of Physical Chemistry and Electro chemistry named after A.N. Frumkina (IFHE) RAS is published in ACS Applied Materials and Interfaces.

Silicone rubbers are a composite material based on silicone and inclusions of silicon oxide nanoparticles. Silicon itself is hydrophobic, but this property can be amplified by creating a microrelief and applying an additional water repellent substance, as did the researchers from IFHE RAS.

Raw and superhydrophobic samples were studied by experts in terms of their water repellent and de-icing properties in two series of experiments: laboratory and field. In the first case, the researchers observed how water droplets behave on the surfaces under study. They tracked the values of the edge angles (angles between the hard surface and the tangent to the surface of the section of liquid-gas, the top of which is at the point of contact of the three phases), the tilt of the surface at which the droplets began to roll down, and a number of other physical and chemical indicators. Particular attention of physicists was attracted by the fact that the studied materials were able to slow the freezing of water at low temperature – for this the authors measured at what speed the drops placed on a particular surface froze.

It turned out that with the help of superhydrophobic coating it was possible to increase the edge angle of water on the surface to 170 degrees. At the same time, the water droplets rolled down at a three-degree slope. This superhydrophobic state was stable in time: the edge angle only slightly decreased when the drop was aging in contact with the surface during the day. It also turned out that on the substrates studied, water droplets did not freeze immediately when cooled below zero. Thus, on the modified surface up to a quarter of all droplets remained liquid up to 20 hours at -18 degrees Celsius and up to 140 hours (almost six days) at -10 degrees Celsius.

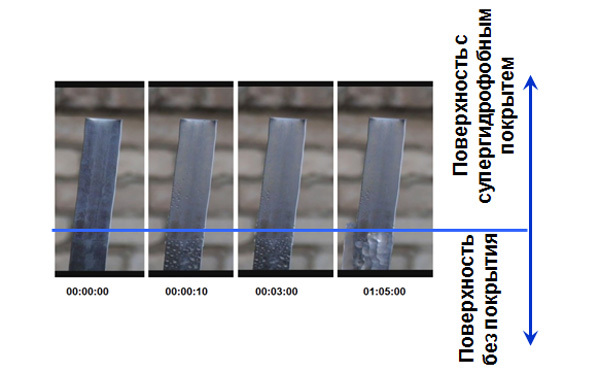

In a series of field experiments, the authors compared the original sample of silicone rubber with superhydrophobic. The plates of these materials were placed on the street at a slope of 20 degrees and with the help of a high-speed camera recorded around the clock what happened to snow and raindrops when they hit the samples. In almost any weather, the superhydrophobic sample remained dry, except during periods when the wind was very weak to blow off the snow. Experiments took place between October and April, so the samples tested almost all known variations of Moscow winter weather.

The authors pay attention to the fact that such a superhydrophobic coating not only gives the samples water repellent properties, but also further strengthens the surface mechanically. Due to this, the micro-relief formed by the inclusion of nanoparticles was little destroyed by external factors, while from untreated silicone rubber nanoparticles were washed out due to the small mechanical strength of the surface of the composite. Scientists suggest that their proposed method will be used in the creation of insulators and protective coatings for power lines and appliances designed to work on the street, including in winte

r.Source indicator.ru